The Butter Bean Picker

Both pictures above are of Daddy. The first was taken probably not too long after he finished his formal education. The second was a few years after the completion of the Butterbean picker

Comfort & Convenience In The Garden

Daddy’s formal education ended in 1919 when he finished the third grade. His real education, the one that molded and forged his work ethic and self-discipline, occurred during the depression. Because money and manufactured goods were so scarce, Daddy made a lifetime habit of not throwing anything away if there was the slimmest possibility that it could serve a useful purpose sometime later (and it didn’t matter how much later the alleged use might occur.)

He also didn’t believe in buying something he could build. He once saw a picture of a Fertilizer Spreader Truck Body in a farm magazine and decided he could use one. (His commercial chicken houses generated tons of spreadable fertilizer.) I’m sure he worked it through mentally and had a fully formed plan prior to the start of construction, but I never saw him commit anything to paper. Using nothing more than that magazine picture and his mental blueprint, he designed and built a fully functional Spreader Body for his 53 Chevy, one-ton farm truck.

The spreader body was one of his larger projects in terms of physical size and mechanical complexity, but it was no different from any other with respect to prerequisite scrutiny. Daddy didn’t commit any resources (time, effort or materials) to a project, before there was a clearly defined, continuing need. But, once he was convinced of a project’s validity, he would bring all of his resources to bear against the problem until it was solved. His resources included his farm equipment, machine shop, carpentry shop and an assortment of left over, surplus and otherwise previously unneeded wood and metal. The uninitiated, casual observer would probably look at his machine shop and say, "I see the scrap metal pile, but where’s the machine shop?" This is a recurring theme that you’ll notice throughout this story. Things associated with Daddy’s engineer/architect side didn’t tend to be very pretty; they were always very functional, but not pretty.

Anyway, using this irregular assortment of tools and materials, Daddy built a rafter raiser, a pecan tree shaker, a bulldozer attachment for his front-end loader, a sawdust conveyer, a dump trailer and numerous, smaller conveniences. All of these contrivances served their respective purposes and indeed were sought out by others in the community because of their utility. But, the undisputed crown jewel of Daddy’s creative ingenuity was his Butter Bean Picker. But, before I get into specifics about the Picker, I must beg the reader’s indulgence for a little more background.

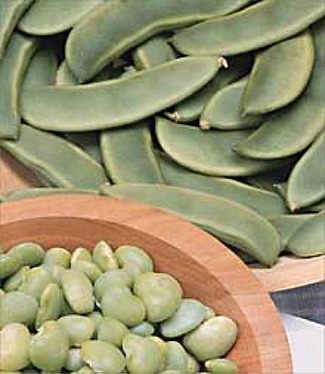

A logical extension of the "Don’t Buy It If You Can Build It" edict was the "Don’t Buy It If You Can Grow It" statute which Daddy also adhered to with determined resolve. Our vegetable garden was larger than most third world farms and some New England counties. And, there was an unwritten rule that produce from this garden could only be harvested by family members and invited guest who, of course, were paid in vegetables. (The standard quantity of vegetables that constituted compensation for a day’s labor in Daddy’s garden was a "mess." I don’t pretend to understand exactly what quantity constitutes a "mess," but this was the term used by both Mama & Daddy to describe this nondescript unit.) By the summer of 1970, none of the children were available to help in the garden. The older ones were married or living away from home and the younger ones were working elsewhere on the farm. So, the task of garden harvesting fell to Mama & Daddy and some of their friends from church. Most of them were retired and of the age group that could no longer do the bending, stooping and kneeling that is a natural prerequisite of harvesting vegetables. This malady of the aging process was the continuing need and original impetus behind the Butter Bean Picker.

The Picker started life as a simple sled pulled behind a farm tractor. (The name Butter Bean Picker is a misnomer because it didn’t actually pick anything. It just provided comfort and convenience for the human pickers.) It consisted of two wooden platforms eight feet long and eighteen inches wide mounted on 5x5 wooden beams for skids. Each platform fit neatly between two rows of butter beans or peas or whatever and there was a row’s width between the two platforms. The platforms were connected by metal arcs at the front and back which allowed a row to pass between them giving the pickers access to a total of three rows—two outboard and one inboard. Since the platforms were mounted on skids that were only five inches high, the pickers themselves were practically at ground level. Once seated on the platforms, the pickers were pulled through the garden in relative comfort at plant level never having to change position if they weren’t so inclined. The Butter Bean Picker provided seating for up to six pickers and with the addition of a few creature comforts (pillows), the drudgery of garden work gave way to a more social atmosphere.

But, the elimination of the bending and stooping problem only served to point out other problems that had been less noticeable by comparison. Most notable among these latent problems was the stifling heat and its attendant humidity. South Georgia in mid-summer routinely features temperatures and humidities in the upper nineties. Not much could be done about the humidity but, as the pickers suggested, some shade would sure be nice. Daddy accepted the new challenge with an enthusiasm normally reserved for revival meeting and market day. First he welded some upright pieces about a foot long to each of the Picker's corners. To this base, he bolted four wooden studs, five feet long to form the vertical supports. He braced the studs against the existing frame and each other before topping the whole ensemble with a small-scale roof assembly. The roofing assembly featured metal "rafters" bowed at an angle that afforded proper runoff if the pickers had the misfortune to get caught in one of Georgia’s midsummer meteorological traditions known as the late afternoon thundershower. Daddy then covered it with an olive drab, army surplus canvas which he secured at the corners with hay baling cord. On the practical side, the roof gave the human pickers the requested shade but it also gave the Butter Bean Picker a silhouette that could have come straight out of the Beverly Hillbilly’s prop department. Like I said, Daddy didn’t worry about making it pretty, just functional.

The pickers were thrilled with the shade, but it was still awful hot. Was there any way Daddy could put in a fan? Daddy answered their call with what he liked to call the air conditioning system. It was actually a three-foot diameter fan attached to the back of the tractor. The fan had been one of many used to cool the chicken houses during the summer. The electric motor had gone out on this particular fan and it had joined the ranks of the "not worth fixing but too good the throw away" sitting in storage awaiting the opportunity that would be its second life. Daddy’s Butter Bean Picker was that opportunity. He removed the electric "guts" of the fan and replaced them with a mechanical setup that could be hooked to the tractor’s PTO or Power Take Off. (This is the shaft at the back of a tractor that provides circular mechanical motion for attachable implements.) He mounted the fan so that it blew across the pickers without getting in their way and was set to a speed approximating that of a ceiling fan. The humidity was still there, but now, the human pickers could harvest vegetables while sitting in the shade with a cool breeze and a social atmosphere very conducive to productivity.

With the passengers now comfortable, Daddy turned his attention to a few engineering problems. As the principle engineer and architect of the Butter Bean Picker, it was incumbent upon him to see to its navigational operation. Since the tractor couldn’t move slowly enough to allow the human pickers to work with the Butter Bean Picker in motion, the operator (Daddy) had to "pull up" every so often. To accomplish this entire evolution he first had to place the tractor and Picker at the desired place in the garden. He would then get off the tractor and join the other pickers until the vegetables from that group of plants were exhausted, get back on the tractor, pull forward eight feet, and repeat the process. With this arrangement, Daddy had only created a substitute bending and stooping problem. To use Daddy’s words, this getting up and down was occurring, "just as regular as a dog goes barefoot." Daddy decided that the solution was to remote the tractor’s clutch operation back to the Butter Bean Picker. He did this with two lengths of cable, a series of pulleys and a chain binder.

A chain binder, as the name implies, is normally used for pulling a chain tight across the load on the back of a truck or trailer. When the handle of the chain binder is in the open position, the two ends are about six inches further apart than when the handle is in the closed and locked position. The binder would become Daddy’s remote clutch. The binder itself was suspended on the Butter Bean Picker’s centerline above the inboard vegetable row. The back end of the binder was attached to a cable that was in turn anchored to a brace on the back of the picker. The front end of the binder was attached to another cable that extended forward through a series of pulleys under the tractor and ultimately attached to the back of the clutch petal. When the binder was open, the clutch petal was fully up, the clutch was disengaged and the tractor would move forward. When the binder was closed, the clutch petal was pulled down, the clutch was engaged and the forward motion stopped. The remote clutch worked perfectly, but it created another problem.

Previously, when Daddy was returning to the driver's seat for each new pull up, he would first crank the tractor, pull forward then shut the tractor down. Now, with the remote clutch in place, he had to leave the tractor running at an idle between pull ups to keep from having to get up to crank it each time. The problem centered around the tractor's exhaust system path; it ended under the tractor's rear axel and the pickers were left directly in the path of the noxious fumes. Sitting in the exhaust had been tolerable when the tractor was only running for a few seconds during the pull up, but constant exhaust was too much. Daddy's options were to either remote the ignition back to the picker or reroute the exhaust. He opted to put a flexible metal extension on the tail pipe and routed it up the front of the picker such that the exhaust escaped above the roof. It had to be left flexible to accommodate the changing angle between tractor and picker, so, instead of a solid permanent installation like Daddy would have preferred, it was suspended with wire from opposite sides of the picker. I wish I could say it was functional without being overly noticeable, but I can't. It was of course very functional, but its long, skinny and shiny appearance added a misplaced rat tail quality to the picker's growing awkwardness. But, there was no time to ponder the feasibility of more aesthetic alternatives, other problems were waiting in the wings.

With the exhaust problem whipped and partial operation of the tractor now possible from the Picker, another navigation problem became apparent. Previously, each time Daddy got on the tractor to pull forward, he reflexively adjusted the steering. Now, without him in the driver’s seat, the Butter Bean Picker garden train could only be moved forward two or three times before the steering started to drift and the tractor started running over plants. This required Daddy to get up from his comfortable spot on the Picker platform and make adjustments. His first solution was to anchor the steering wheel in a fixed position. This basically served to extend the time between adjustments but didn’t eliminate the problem. The final solution obviously had to be some means of continuous adjustment from the Picker. Daddy found a steel rod that was as long as the picker and mounted it above the right side platform. He took another, shorter rod and bent it into a semi circle to form a steering wheel which he looped around and welded to the longer rod. Using two more rods, a sleeve connector and a universal joint, he routed the remote steering column up over the back of the driver’s seat and down to the center of the tractor’s steering wheel. With the remote steering innovation, most critical tractor operations could be controlled from the picker. Which was good, since sharing the driver's seat with the linkage assembly of rods and universal joints made conventional driving a difficult proposition.

Now that the tractor’s motion could be started, stopped and steered from the Picker, there would be no need to operate it at all from the driver’ seat if the throttle could be remotely controlled as well. The tractor’s throttle was the hand operated variety that held its last position until manually changed. It would be easy enough to attach a cable or rope to the throttle handle to pull it down (accelerate) but Daddy would have to attach a second cable that was routed via a pulley to the front side of the throttle handle to pull it back (decelerate). To give both acceleration and deceleration control in a single hookup, Daddy simply attached a broomstick to the throttle lever. The opposite end of the broomstick was within easy reach from the front of the Butter Bean Picker. After this modification, Daddy would drive the whole assembly from barn to garden without ever getting in the driver’s seat.

Along the way, the Butter Bean Picker began to take on celebrity status. Maybe it was the uniqueness of the contrivance itself, maybe it was the awkwardness in Daddy’s "function over form" approach to engineering, I don’t know. But the fact remains that through no design or desire on Daddy’s part, people were taking notice and following the Butter Bean Picker’s progress. For some, there was entertainment value in its increasingly strange appearance, others had a genuine interest in the engineering, but they all smiled and left Daddy with encouraging words to continue. And he did.

As I mentioned earlier, the Butter Bean Picker cast a rather distinct silhouette and our neighbors while curious were kind enough to not laugh out loud during its earlier stages of development. But, in the later stages, even the most disciplined poker face in the county would have had trouble suppressing a grin upon first glimpsing this labor saving marvel.

Imagine for just a moment that you are an unknowing, casual observer viewing the Butter Bean Picker for the first time. Try to grasp this mental image. You start by noting a very noisy, two-stage contraption on the road. Your eye is first drawn to the source of mechanical noise, a farm tractor, with the driver conspicuously absent from his appointed place. The tractor is moving down a dirt road at a speed somewhere between a brisk walk and a jog. You follow the irregular contour to the back half of the contraption and your next visual stop would probably be the army surplus canvas roof surmounting a ground level platform. The platform is host to the other source of noise, five senior citizens seated cross-legged on pillows and socializing loudly (above the tractor noise). A sixth senior citizen is apparently operating the tractor while standing at the front of the platform and constantly changing position around a large fan and shiny, flexible pipe to look up over and around the tractor that is both pulling the contraption down the road and blocking his view of the road. Logic fails you. All attempts to attach some semblance of reason to the evidence before you end in a hung jury. The closest you can come to explaining the full visual package before you is a misplaced, rough cut, land locked, pontoon party boat with a very animated skipper out for a casual, early morning dirt road cruise. Having been witness to the scene described above, I can truthfully report, that the human compulsion to go forth and enlighten the unknowing with reports of the bizarre hasn’t been diminished by the advent of modern news services. Several of my classmates and peers made a point of seeking me out to tell me of second and third handed accounts of Butterbean Picker sightings by some of their family, friends or distant relatives. I would normally nod politely, confirm the Pickers existence and validate the sighting.

I arrived home for dinner one day during the later stages of the Butter Bean Picker’s development. Daddy was still on the job. Noting all the conveniences that he had added since the last time I saw it, I sarcastically asked when he was going to put in the bucket seats. He calmly reached over, picked up a foot tub, placed it upside down on one of the platforms and said, "There’s your bucket seat, now gimmie a hand with this."

Aesthetics were never a consideration in the Butter Bean Picker’s design or construction and if a battleship had managed to negotiate the dirt road by our house, I don’t think it would have turned any more heads. Daddy never got a patent on the Butter Bean Picker, but to the best of my knowledge, no one has ever copied the design.

End of story

Epilog:

In the highest traditions of "conservative meets bizarre," I’ve often played out a mental scenario that features Daddy and crew on the Butter Bean Picker headed down the dirt road to the garden when they’re spotted by a State Patrol.

Dispatch, this is Trooper Glen. I’ve got . . . something on the dirt road just off highway 121 over here behind the old country store.

It appears to be a Massey-Ferguson tractor pulling . . . a platform or something. But there’s no driver on the tractor.

Yes, there's people on a platform lookin’ thing behind the tractor and there’s a fellow standing up at the front of the platform behind a big fan, lookin’ out around the tractor. He’s probably doin’ the driving, but I can’t be sure.

Cause there’s about a half dozen old folks sitting frog-legged on the platform and it’s got a low roof, looks like it’s made out of an old army canvas, blocking my view.

No, it ain’t a tobacco picker or corn combine, I know what they look like.

No, it ain’t got a license plate or brake lights, but it ain’t on the highway. Besides, I don’t think it’s got wheels.

Cause it’s digging out two heavy tracks in the dirt like it was on skids or something.

No, he’s not driving too fast, not going much faster than a good walk.

No, not driving erratic either, right down the middle of the road, slow and straight.

No, they don’t appear to be in any danger, in fact they’re talkin’ and laughin’ and apparently having a pretty good time.

No, this ain’t a bunch of old folks having a hay ride at 6:30 in the morning.

No, it ain’t got seats either. I told you, they’re sitting cross-legged on the platform, I think most of them got pillows to sit on.

No, they look sober and I think they’re headed somewhere to work judging by the way they’re dressed. You want me to pull them over?

Okay, I’ll leave them alone. How about let’s keep this to ourselves? I’d just as soon not have to write this one up.